Contact us

-

EUROCADE

Parc d'activités du Moulin

82 rue de la Feschotte du Haut

25490 DAMPIERRE-LES-BOIS

FRANCE - Contact us

All our control resources enable us to meet all applicable requirements throughout our production processes.

In this way, we comply with supplier and customer recommendations.

- Integrated into the K341 type cutting machine. It measures the crimp height and compares it with the theoretical crimp height, and until there is a match, production cannot be started.

- Manual with digital display.

- Q1210 integrated into the cutting machine to measure tensile force (up to 1000 Newton)

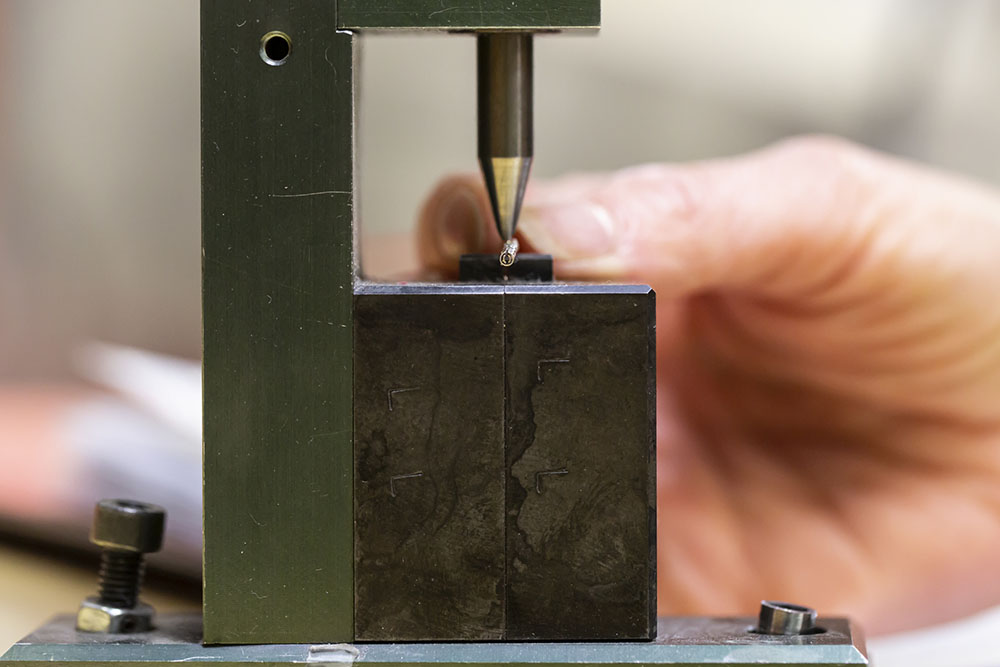

- Manual type EPT_1000 motorised device for measuring the force leading to breakage The results are recorded in the form of a force-time curve.

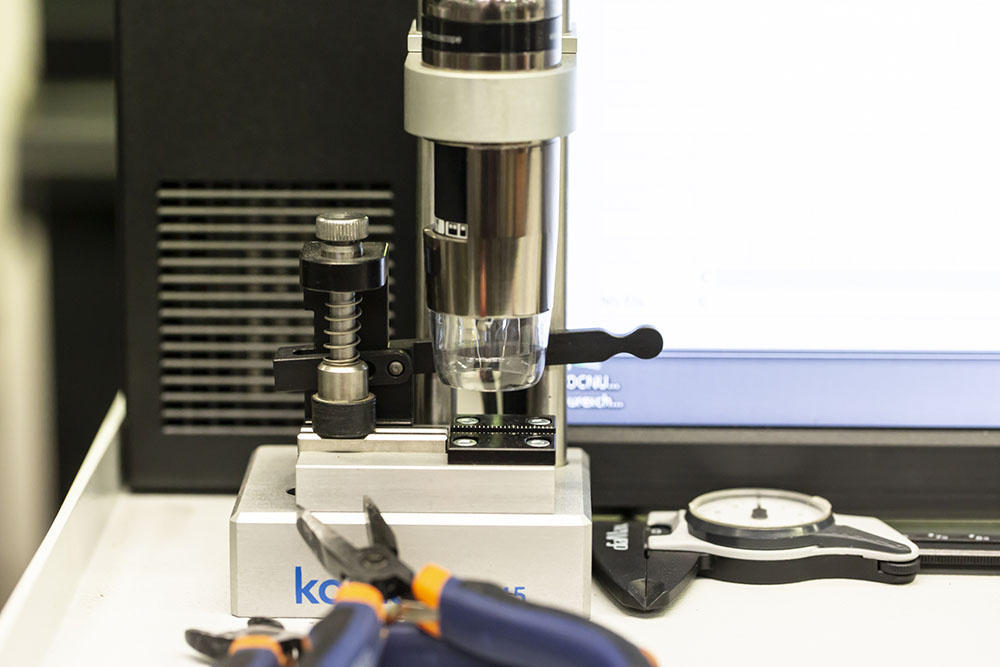

Integrated into the Alpha550 cutting machine, it allows quality control of stripping and crimping, even for contacts with very small cross-sections.

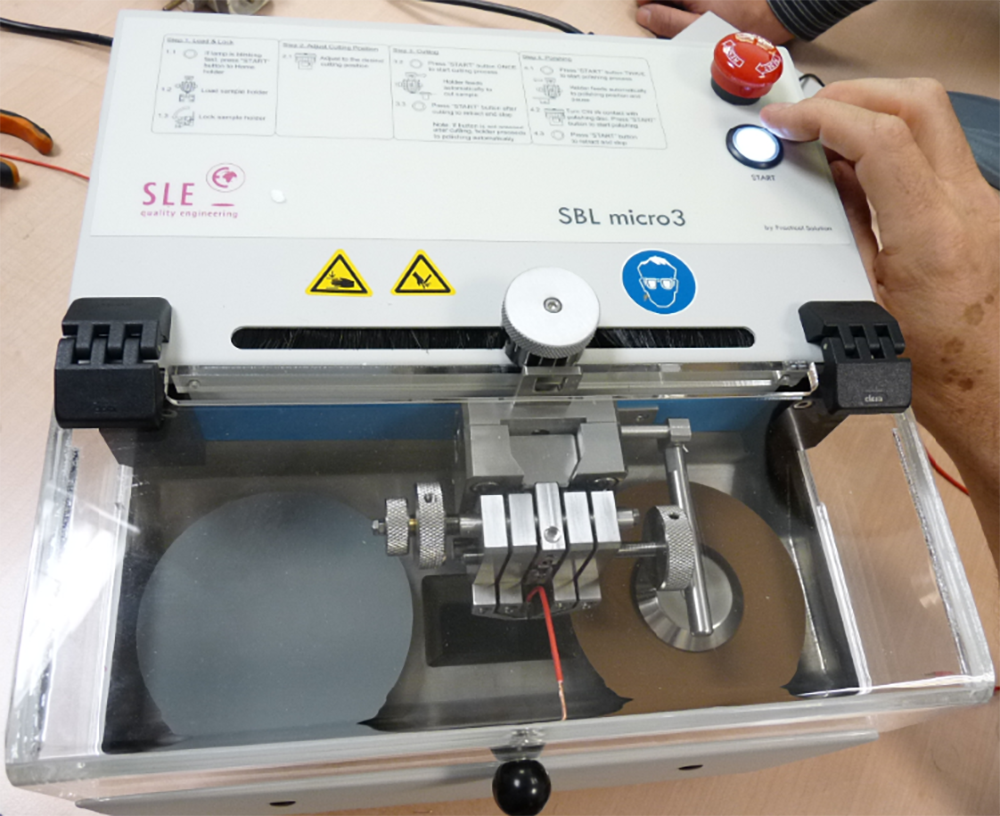

- Portable micrography laboratory combined with an AUTOMATIC cutting and polishing module.

- After the cutting and polishing process, the surface of the sample can be treated with the pen by chemical electrolysis, creating a clear contour.

- A laboratory microscope can be used to observe and analyse the image of the cross-section of the crimped connection..

- The SL Vision III software enables all the measurements to be taken in accordance with the international standards required by the automotive industry in particular. A final report validates or rejects the crimp.

Are you looking for a reliable partner for your measurement needs? Look no further! At EUROCADE, we combine expertise, precision and innovation to offer you tailor-made solutions.